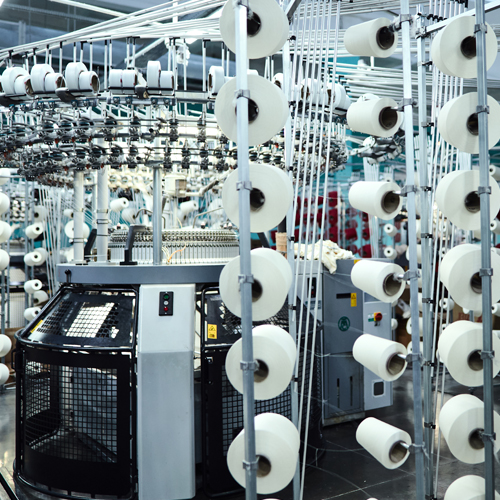

«T-Style» LTD was established on March 6, 2008 on the basis of the Rivne Lonokombinat. Textile industry is the scope of our activities. «T-Style» LTD produces and sells various types of fabric like: single jersey, pike fabric, plush, interlock, rib fabric, two thread fleece, three thread fleece etc. We use cotton, viscose, acrylic, polyester yarns and their blends, and also sew clothes from this fabric. In nowadays our company brings together more than 1,500 employees. The company has reorganized and renovated a significant part of the workshops where textile fabrics are produced. The clothes are sewn on the most modern and high-performance equipment from the well-known manufacturers. The Rivne Lonokombinat is the leader on the Ukrainian light industry today in capacity and development rates. In addition, the country’s leading developers have recognized our company as the most successful domestic retailer in the last few years. We constantly keep the high development dynamics, integrate the latest technologies in production and trade, and continue to be the favorite brand for our customers.

Our company

By the way, you can explore and see the whole process of production during the visiting our factory – We would like to see you soon!

Production capacity

Today, the company’s production capacity is more than 20 tons of canvas per day. However, the company «T-Style» continues to work on widening of its own production facilities, for example, in 2018 we put into production our own denim producing. It is expected to receive a special compactor from American company FAB-CON. This item gives opportunity to process viscose fabric better. Moreover, we constantly try to increase the capacity of the sewing shop, in particular, we plan to automate the tailoring of polo shirts.

A powerful team of more than 1500 employees

Energy saving and energy efficiency

«T-Style» LTD takes care of its employees and environment. Heat exchangers and filters are installed on all equipment where it is possible. A powerful solid fuel boiler house from Austrian company Polytechnik Luft-und Feuerungstechnik GmbH was launched at the factory in December 2015. The new boiler house gave us the opportunity to almost completely turn away from the usage of natural gas and reduce the cost of energy for our production. As a result we reduced the cost of producing the knitted fabric. It will definitely increase the competitiveness of our products in Ukrainian and world markets. In addition, our company is implemented for a while the energy-saving technologies in production. In particular, the lighting was completely replaced from conventional to energy-saving lamps inside the workshops and on the whole factory. The latest water-treating equipment has been installed and put into operation from Dutch company «Nijhuis Industries».